Artificial Intelligence

12 min read

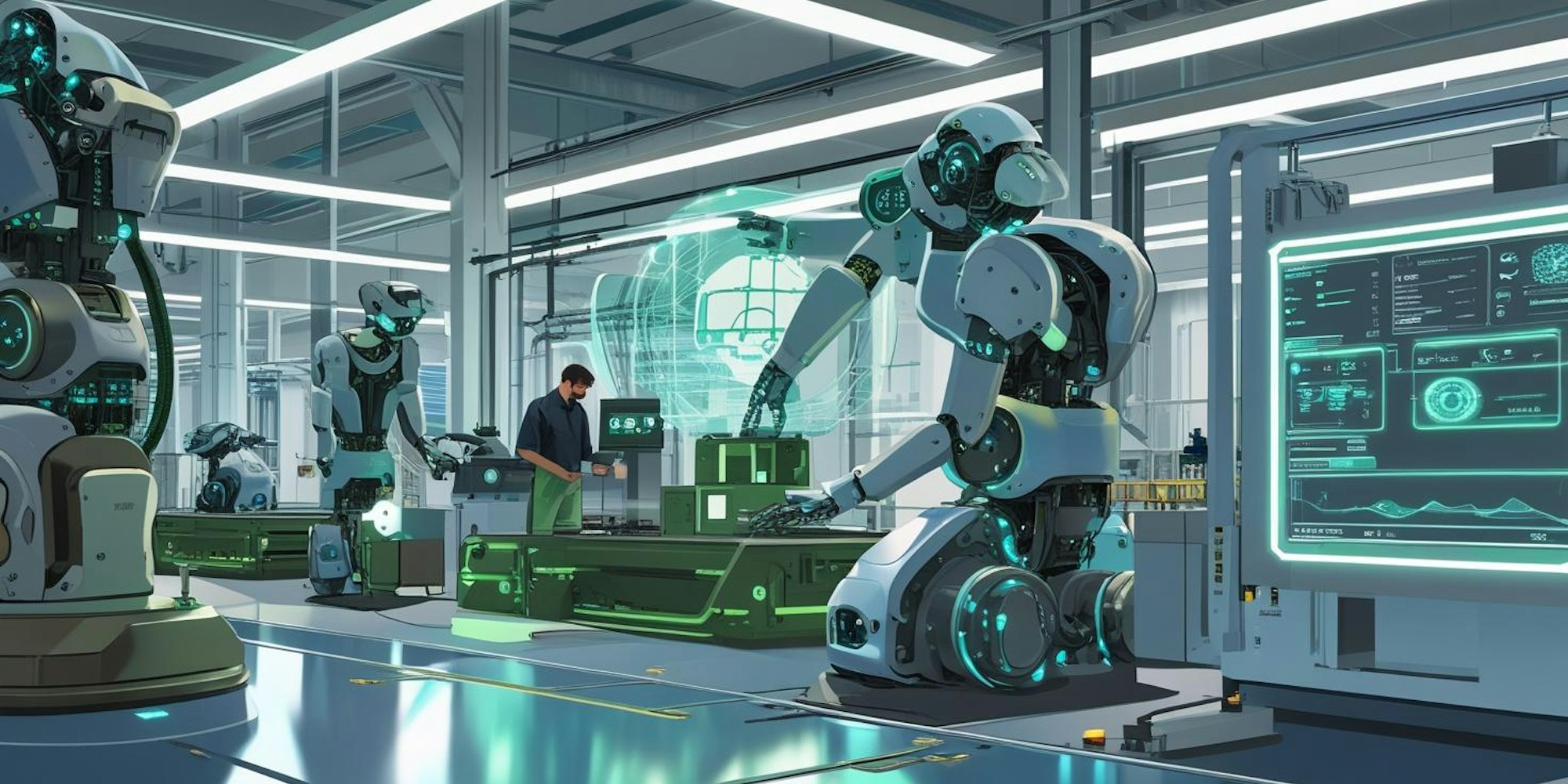

Digital Twin Technology: Revolutionizing Industrial Systems Through AI Integration

The integration of Digital Twins and Artificial Intelligence (AI) is transforming the industrial landscape by creating sophisticated virtual replicas of physical assets, processes, and systems. This synergy enables unprecedented levels of monitoring, prediction, and optimization capabilities that are revolutionizing manufacturing and industrial processes. As we delve into the world of digital twin technology, it becomes evident that this innovation has the potential to disrupt traditional industrial systems and propel businesses towards a more efficient and productive future.

Understanding Digital Twins in Industrial Systems

Digital twins serve as dynamic, virtual representations of physical industrial components and systems, maintaining real-time connections with their physical counterparts. Unlike traditional simulation models, these digital replicas continuously update based on operational data, providing deep insights into industrial operations and enabling advanced predictive capabilities. The real-time data analytics and predictive maintenance capabilities of digital twins allow industries to optimize their operations, reduce downtime, and improve overall efficiency. For instance, a study by Gartner found that digital twins can help organizations reduce maintenance costs by up to 30% and improve asset utilization by up to 20%.

The concept of digital twins is not new, but its application in industrial systems has gained significant traction in recent years. The increasing use of IoT devices and advances in AI have made it possible to create highly accurate digital replicas of physical systems, enabling industries to simulate, predict, and optimize their operations with unprecedented precision. As digital twin technology continues to evolve, we can expect to see even more innovative applications of this technology in various industries.

AI Integration: The Game-Changer

The fusion of AI with digital twin technology creates a powerful synergy that amplifies industrial system benefits. Predictive maintenance, real-time process optimization, and quality control are just a few examples of how AI-powered digital twins can transform industrial operations. For instance, GE Aviation's digital twin implementation for jet engines resulted in a 25% reduction in maintenance costs, 20% improvement in engine efficiency, and 40% decrease in unplanned downtime. Similarly, chemical manufacturing facilities using digital twins have achieved a 15-20% increase in production yield, 25% reduction in energy consumption, and 30% decrease in waste production.

The integration of AI with digital twins enables industries to analyze vast amounts of data, identify patterns, and make predictions about future outcomes. This predictive analytics capability allows industries to optimize their operations, reduce risks, and improve overall efficiency. For example, automotive manufacturers implementing digital twins report a 40% reduction in product development time, 25% decrease in quality issues, and 35% improvement in first-time-right production.

Practical Applications and Success Stories

The application of digital twin technology is not limited to any one industry. Smart factories, energy sector, and automotive manufacturing are just a few examples of industries that have successfully implemented digital twins to improve their operations. For instance, Siemens' Amberg electronics plant demonstrates the power of digital twins, achieving a 99.9% product quality rate, reducing production errors by 80%, and decreasing time-to-market by 50%. Similarly, a European power company's implementation of digital twins resulted in a 20% reduction in maintenance costs, 15% improvement in plant availability, and 25% decrease in operational expenses.

The success stories of digital twin implementation are numerous, and the benefits are undeniable. BMW's implementation of digital twins in their production lines achieved a 15% reduction in production time, 25% decrease in quality issues, and 30% improvement in assembly line efficiency. As digital twin technology continues to evolve, we can expect to see even more innovative applications of this technology in various industries.

Implementation Strategy and Best Practices

Implementing digital twin technology requires a well-planned strategy and best practices. The technical integration framework should include infrastructure assessment, data management strategy, and AI integration process. Infrastructure assessment involves evaluating existing systems and capabilities, identifying integration requirements, and establishing data collection protocols. Data management strategy involves implementing robust data collection systems, ensuring data quality and consistency, and establishing secure data storage solutions.

The AI integration process involves deploying appropriate AI algorithms, establishing monitoring systems, and implementing feedback loops. Change management and training programs are also essential to ensure a smooth transition to digital twin technology. Cost management and return on investment (ROI) analysis are critical to justify the investment in digital twin technology. By following these best practices, industries can ensure a successful implementation of digital twin technology and reap the benefits of this innovative technology.

Challenges and Solutions

While digital twin technology offers numerous benefits, there are also challenges associated with its implementation. Technical challenges, such as legacy system integration, data quality, and security concerns, can be addressed by implementing middleware solutions, advanced data validation systems, and multi-layer security protocols. Operational challenges, such as skill gap, change management, and cost management, can be addressed by providing comprehensive training programs, developing structured adoption strategies, and creating phased implementation plans.

The future implications of digital twin technology are significant, and industries that successfully implement this technology will gain a competitive advantage in their respective markets. As digital twin technology continues to evolve, we can expect to see even more innovative applications of this technology in various industries.

Future Implications and Trends

The future of digital twin technology is exciting, with emerging technologies such as 5G network integration, edge computing, and extended reality (XR) expected to further enhance the capabilities of digital twins. Industry experts project that by 2025, 89% of industrial companies will implement digital twins, resulting in a 60% reduction in product development time and a 40% decrease in operational costs.

The integration of digital twins with other emerging technologies will create new opportunities for industries to optimize their operations, reduce costs, and improve efficiency. As digital twin technology continues to evolve, we can expect to see even more innovative applications of this technology in various industries.

Conclusion

Digital twin technology, powered by AI, represents a fundamental shift in industrial system management. The technology's ability to provide real-time insights, predictive capabilities, and optimization opportunities makes it an essential tool for modern industrial operations. Organizations that successfully implement these solutions while addressing associated challenges will gain significant competitive advantages in their respective industries.

To stay ahead of the curve, industries should start exploring digital twin technology today. By investing in digital twin technology, industries can optimize their operations, reduce costs, and improve efficiency. The future of industrial systems is digital, and digital twin technology is at the forefront of this revolution.Contact us today to learn more about how digital twin technology can benefit your business.#DigitalTwinTechnology #AI #IndustrialSystems #Innovation #FutureOfIndustry

Reference Links:

https://www.ibm.com/think/topics/what-is-a-digital-twin

Get the latest updates

We only send updates that we think are worth reading.